The three friends approached the old factory. It was mid-morning on Sunday, September 9, so traffic on South Broadway was slight, reducing the likelihood of being seen. They scanned the perimeter, took a quick glance back. Then they walked through the unlocked gate and into the alleyway, looking for a way in.

The reasons for staying away from Gates were the same reasons for going inside. Behind its thousands of grime-caked windowpanes, the former factory was massive, antique, abandoned, filled with air ducts and conveyor belts and who knew what else.

That mystery is what attracted the three housemates, who were looking for a little diversion and adventure before their college classes kicked into high gear. Adam Buehler, who had his camera, walked alongside Michael Craig while John Polzin led the way — as usual. Known as Johnny to family and friends, he had just begun his final semester at Metropolitan State College of Denver, where he was earning a bachelor's degree in botany. But the 23-year-old was no science geek. At 6' 2", Johnny was nearly 200 pounds of solid muscle and athleticism. Above his heart was a flower, a Stargazer Lily, which he'd had tattooed on his chest when he started his official study of plant life. With subsequent ink sessions, the flower had grown around his shoulder and onto his back, a forest of vines and petals.

Nothing blossomed inside Gates except rust on the old machinery, but the factory was a hidden part of the world. And for Johnny, that made it worth seeing.

The friends found an unlocked door and stepped inside. After the sunshine, their eyes had trouble adjusting to the dim light beyond the threshold.

Johnny went first. A few steps later, he was gone.

Joe Hicks read about the accident in the newspaper the next day. The story was barely a blurb, and simply reported that the fire department had rescued a man who'd fallen down an open elevator shaft at the Gates plant. But that was enough to shock Hicks. The night before the accident, the University of Colorado student had been exploring the factory himself. He and a buddy had snuck inside the building about midnight, armed with flashlights and waterproof boots, and hadn't emerged until daybreak. They'd missed the rescue by only a few hours.

"It was really weird, because we actually exited out that side," Hicks remembers. "I've racked my brain trying to remember places where he could've fallen in. There are lots of places where elevator doors had been pried open and it's just a straight drop down."

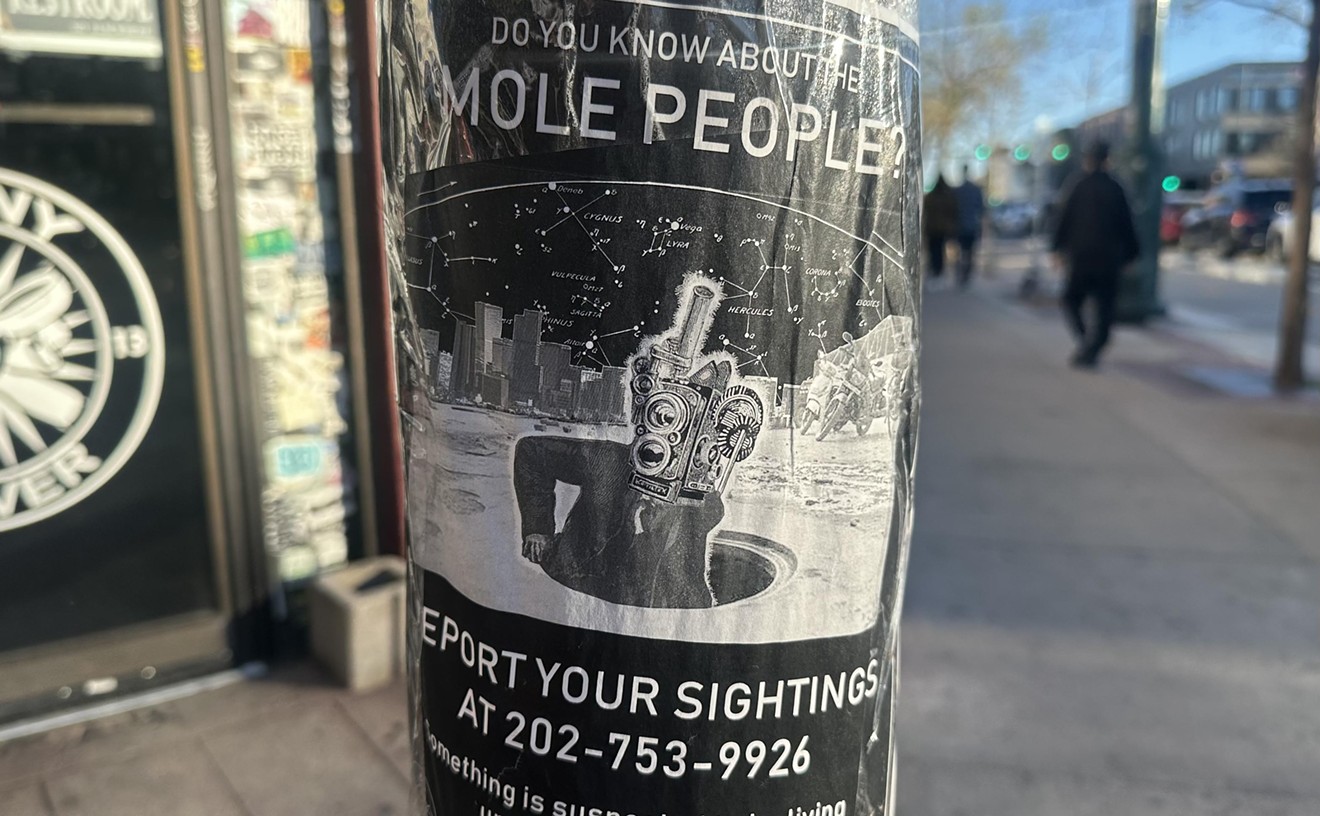

For Hicks, going into Gates is both a hobby and a sport. That's what urban explorers do, he explains: seek out abandoned, manmade structures and get inside them to see what they can see. Subway tunnels, empty mental hospitals and forgotten shopping malls are all fair game. Enter without breaking in and exit without getting caught. Post pictures on the Internet and trade tips with your peers. Hicks runs a website called Denver Drainers (www.denverdrainers.org) that lists the storm sewers and other tunnels beneath the city and describes what an explorer can find there.

Compared to East Coast cities with their massive metropolitan overlays and former manufacturing centers in the Rust Belt, Colorado has few options for explorers, mostly abandoned mines and forgotten missile silos ("Search Party," November 20, 2003). By far the most popular exploration destination is Gates, conveniently located south of downtown just off I-25.

A few years ago, Urban Explorers, a reality show on the Discovery Channel, featured Gates in a lengthy segment. The on-camera hosts crawled through steam tunnels beneath the buildings, explained the purposes of long-dormant machinery, scaled the famous water tower on the roof. The show didn't last long, though. Since the network felt obliged to obtain prior permission from property owners — in the case of Gates, a redevelopment company named Cherokee Denver — the action inside looked artificial and painfully cheesy.

Equally bad, but in a campy, B-movie way, is the sci-fi horror flick Shadow Walkers, which was filmed at Gates in 2005. When the factory went largely offline in the early '90s, there were more than 2.3 million square feet of industrial and warehouse space on the property. A little less than half of that could be attributed to Unit 10, where the majority of the manufacturing had taken place. Built in 1919, it was one of the oldest remaining structures on the site.

"It was really almost perfect for us," says David Marchiori, producer of Shadow Walkers, whose plot follows a group of soldiers and scientists being stalked through an underground bunker by a mutant monster. "It was supposed to be this kind of old, out-of-date, dormant facility, with circa 1910-to-1970s equipment. [Unit 10] is a million square feet of creature haven. Every corner you turn is just some new, creepier inspiration."

Between takes, the actors were asked to wear protective breathing masks to limit their exposure to the dangerous chemicals and asbestos that still contaminated the buildings and the soil below. And those weren't the only dangers. Thieves had been stripping copper wiring and other electrical fixtures from the factory, which meant that areas were torn up and power for the shoots had to be provided by rented generators, whose cords snaked across the floor. Crew members frequently stumbled on evidence of squatters, including discarded clothing and food wrappers. The brave few who ventured into the factory's darkest corners had to watch their step because of all the used syringes and crack pipes.

About three weeks into the film project, the movie crew arrived on the site one morning and saw that someone had scrawled "Death to the Daywalkers" in red paint across the entrance. The message was clear, Marchiori says: Gates had become its own underground province, and the natives were getting restless.

The movie-crew members were authorized visitors. But Gates also attracted graffiti crews that roamed the upper levels, covering the windows with their work. "Once we got the rooftop spots and the water tower, it sort of turned into a contest to get all the best spots," says ACEE, a leader of RTD, a local crew whose initials were spray-painted on the tower for months. "Once the windows were done, pretty much any kid and their grandma could tell that was the spot to be. Then everybody came down there and started painting."

Cherokee Denver had already hired a security company to periodically patrol the buildings at night, and now it brought in a graffiti-abatement team to cover the work of the crews. But nothing stopped the curious from coming. Particularly the urban explorers.

"Places like Gates — there has been so much traffic through there, it's sort of like a public forum," says Hicks. "There are so many stories to tell. It's what makes it interesting."

Most of the hard-core urban explorers in this town are geeks and hackers looking for an adrenaline kick away from their computers that isn't too illegal. But local law enforcement often doesn't appreciate the distinction. Legend has it that a few years ago, a police dog took a bite out of one Gates adventurer. And in mid-September, shortly after Hicks spent a night exploring the factory, police spotted Zachary Helm and a friend exiting one of the buildings. The 32-year-old Helm runs the Denver Hearse Association, a group devoted to tricked-out funeral cars. This was his seventh time inside Gates, whose impending demolition had induced him to break a cardinal rule of urban exploring: He took souvenirs — a small sign from one of the buildings and a few switch boxes because they looked cool. Police charged Helm with felony burglary, and he spent three days in jail before posting bond.

"You have no idea how large that complex is until you really get in there," says Helm, who was able to plead the charge down to a misdemeanor. "It's absolutely amazing. Just the roof alone is like a small city."

A small city that attracts many strangers.

Though John Polzin liked to explore, he was not an official urban explorer. In fact, he never knew the activity had a name, his friends say. He was more of a nature guy, an all-around vagabond. He scaled fourteeners, hopped freight trains, climbed rainforest canopies in Hawaii and biked through the Nevada desert during Burning Man wearing only a loincloth. He liked to go on long runs with his father in the foothills near where he'd grown up in west Arvada.

Hicks is also a middle-class child of a 'burb, Littleton, where the built environment of chain stores and office parks stands in sharp contrast to an old-school industrial icon like the Gates plant.

"It's got this defined American production feel to it," says Hicks, who researched the factory's history online before starting his exploration. "Even when I was in there, I could kind of imagine the industrial revolution with people clocking in and busting asses on the line. Or during World War II, when they made Jeep tires. I've never really known anything like that, when America still made things. Now everything is outsourced overseas, and there's nothing left except this huge empty thing."

Charles Gates Sr. had a saying: "Throw your hat across the creek!"

He would say it at board meetings, to business associates and in company newsletters. Throw your hat across the creek! It was an Old West expression that had something to do with pioneers tossing their hats to the other side of waterways as incentive for covered wagons to cross. He liked the symbolism of it. Independent men taking risks to forge new frontiers. He thought that the Gates Rubber Company, which he'd built out of nothing along the banks of the South Platte, was an extension of that same entrepreneurial, Western spirit.

A former mine superintendent, in 1911 Gates had paid $3,500 for the Colorado Tire and Leather Company, located at 1025 South Broadway. He came up with the idea of a durable tread, a strip of leather that wrapped around the metal wheels to extend their lifespan, and based on the success of this invention, within a year the company had expanded to seventeen leather cutters and stenographers to handle the mail-order business. But Gates didn't want to waste any leather scraps, so he decided to make horse halters, too, and gave Buffalo Bill Cody a half-dozen to test on his wild mustangs. Cody liked them so much that he agreed to endorse the halters, and Gates soon became the nation's largest horse-halter manufacturer.

The tire business was on a roll, too, and Gates next introduced the half-sole tire cover, which replaced the leather with a rubber tread set in a fabric carcass. This innovation completely changed the industry, not just making tires more durable, but adding traction. The company expanded further down South Broadway. Then in 1915, an employee inadvertently invented the Vulco Flat Belt, with rubber replacing the leather straps of engine belts. Charles Gates's brother John soon improved on this with the rubber V-belt, which replaced the hemp rope then used to run automobile-engine fans and quickly revolutionized the belt business.

When rubber prices dropped in the 1920s, Gates renamed the business the Gates Rubber Company and began making actual tires, including the Super Tread and a slew of other products. On the roof of the factory, near the water tower, Gates built a testing facility where a tire attached to a pole could roll along a circular track. But he didn't stop there. In keeping with the City Beautiful movement that was sweeping the country, he added a rooftop garden featuring grand pillars and vine-covered lattices, as well as an ornate dining area where Gates could host orchestras, socialite parties and even boxing matches.

Sales grew to more than $3 million annually. Facilities were opened in Chicago and San Francisco, and the Denver plant was dubbed the "West's biggest factory." In a newsletter, Gates opined that his company symbolized the dawn of a new day in industrialism: "Old-fashioned methods are dying, and the greedy labor-sweating employer whose horizon is no wider than the disc of a dollar is slowly being pushed to the wall. The men of the new school inject a broad humanity into their relation with the wage-earner and find their return in increased satisfaction and contentment — and efficiency."

Gates's rapid growth proved that it was possible to have a manufacturing seat west of the Mississippi. "The rise of the Gates Co. has given the West considerably more recognition than it had been receiving from Eastern leaders in automobile and rubber manufacturer organizations," the Rocky Mountain News declared in 1927. "Denver, President Gates concedes, is not 'industrially minded.' Very likely, he suggests, that's the only reason why there are not more factories here the size of his own."

By the 1930s, the complex had grown to thirty interconnected buildings over a 25-square-block area that manufactured some 120 products, including the world's first synthetic belt. During World War II, when the supply of raw rubber from Indochina was cut off, Gates went into round-the-clock war production, making everything from tires and gaskets to gas masks and TNT buckets. Newspaper stories described the complicated process of producing synthetic rubber from scratch, as "grizzled men" dumped the base materials into huge vats, "gray-haired women" stirred in chemicals and a "young girl" trimmed the still-warm products.

In the 1950s, Gates grew into a multinational corporation with dozens of plants across the Western hemisphere. When a strike by the United Rubber Workers Union in the '60s immobilized U.S. production for months, the company pushed for even greater geographic diversification, which put it at the forefront of the business trend now known as globalization.

At its peak, the Gates factory in Denver employed over 5,500 people. One of them was Egon Topp, who worked as a maintenance electrician at the plant for thirty years. Now 78 and living in Northglenn, Topp was raised in Germany, where there were few jobs for young men. He emigrated to Canada, then moved on to Denver, where he found work at Gates in 1961. At the time, the thousands of employees were divided between three shifts; as one shift clocked out, the next shift was already clocking in. It was Topp's job to make sure that the vast array of machinery was ready to start at the push of a button.

"There could not be any downtime," he explains, since any breakdowns or problems with the power generators could mean tens of thousands of dollars in lost productivity. The complex even had its own power plant. Topp's role required that he know every sector of the massive operation. The biggest was the tire division, which could produce up to 2,500 tires daily. From the rubber tires to their steel rims, everything was made at the plant.

The company kept growing — and diversifying. Under Charles Gates Jr., the company invested in Learjet, and also got into the development business in Colorado Springs. At the Denver facility, Gates created a health center complete with doctors and dentists. In 1971, the company opened a $21 million tire plant in Littleton, which could crank out 3,000 tires daily. But that facility was closed just three years later, when Gates discontinued tire production altogether. By then it had expanded into myriad products such as plastic bottles, cassettes and battery casings.

During the '80s, Gates began acquiring competitors in Europe and started a relentless push into Asia, India and China. Although the company built a new administration building at 990 South Broadway in 1985, two years later it announced that it was closing most of its manufacturing divisions in Denver, eliminating thousands of blue-collar jobs. "Soon only the belt division was left," Topp recalls. "Whole sections were shut down. They were laid off." When the union contract finally ran out in 1991, many more Gates workers simply retired, Topp included.

In 1996, what was by then known as the Gates Corporation was subsumed by Tomkins PLC, a British conglomerate, ending 85 years of family ownership. The company chose to maintain an administrative headquarters in Denver, but moved it to a new office building at the edge of the Platte Valley, which is reserved for upper-echelon management. The South Broadway facility was shuttered.

Topp has only fond memories of the company from which he receives a pension check every month, though it now comes stamped with the name of the British firm that purchased Gates. And he still recalls the Christmas party that Gates held every year at the Denver Coliseum, where all the children of employees would get presents. His daughter is a grown woman now, with a grown daughter of her own.

A few years ago, he was even able to go inside the old plant, when that granddaughter worked on the horror movie filmed in the basement. "It was just the basement floor," he remembers. "Not one machine was left from the tire division. Nothing. Thirty years."

It was a pit. A big, fucking pit. The floor just dropped away into a ten-foot wide abyss, and then started again level and sturdy on the other side. They heard yelling, and screamed their friend's name.

Mike pulled out his phone and called for help. He was the dweeby red-headed kid no one would talk to in middle school — but Johnny had marched right up to him and announced, "Hi. I'm John Polzin." The only boy in a family of three sisters, from then on Johnny regarded Mike as his brother.

While Mike made his frantic calls, Adam decided to climb down into the shaft. They didn't have a flashlight; they hadn't thought they'd need one. Adam made it down one level, then another. The shaft went farther. Five feet below basement grade, thirty feet down, he finally reached the bottom and stepped into water that came up to his shins. He felt around and found Johnny. His friend was still breathing. Adam remembers that the water smelled grimy, like corrosion and stale air.

Adam is thin and bookish and looks younger than his 24 years. One of his first memories of Johnny is the time that Johnny helped him make soup. They didn't live together then; Adam had just joined a mutual friend over at Johnny's house for dinner and offered to help. Johnny seemed to know what he was doing — he'd taken cooking classes — so Adam asked for instructions. How big should he cut the carrots? What about the potatoes? Spices?

"I don't know, man," Johnny had answered. "Do it however you want."

But he didn't say it like he didn't care how Adam made the soup. He said it like it was more important that Adam do the soup his own way, whatever way that was. Adam had never thought of it like that.

"I felt that same kind of push from him," Adam says now. "I saw him encouraging people and myself and everybody else to do what they wanted to do and not worry about what people told them. Just follow whatever you think is right."

Johnny was like that about everything. Last year, after seeing some tap dancers at Boulder's Dinner Theatre, he'd asked his sisters to get him lessons for Christmas. But when he showed up at the Arvada Center in his brand-new tap shoes, he was the only student who wasn't a girl under the age of ten. His sisters suspect there may have been a class recital, but he refused to clue them in on the date and time.

Johnny's interests were nothing if not eclectic. He convinced his father, Larry Polzin, to take accordion classes with him. He practiced making funny faces in the mirror the way others lift weights. He served on his college's student election commission. For birthday gifts, he wrote letters that methodically detailed what he viewed as the recipient's talents and unique qualities. He volunteered at the Denver Botanic Gardens and gave tours of the fauna and flora, sharing Latin names, geographic origins, all of it.

His parents were planning a move to Seattle in January. Johnny was going to move there, too, and get his master's in botany while working with his father in a new business creating gold-leaf plaques. He wanted to own a small farm, grow organic vegetables and save the world.

But in the blackness of the shaft, everything had changed.

Adam isn't sure how long they waited. Ten minutes? Twenty? Then the Denver Fire Department arrived, and the Engine 11 team put its ground ladder down the shaft to provide access for rescuers. The basement elevator door was pried open so that Johnny could be removed safely.

A body with less of a he-man physique might never have survived such a fall, and even so, Johnny's injuries were bad: broken bones, internal injuries. He drifted in and out of consciousness. Up top, local TV camera crews had already arrived. Mike and Adam refused to speak with reporters.

They did speak with Denver Police Department sergeant David Williams. The factory is part of Williams's sub-district in District 4, and he is quite familiar with the different types of people that Gates attracts. Since 2003, when the factory officially closed, police have been dispatched to the property at least twelve times on burglary reports, and nearly a dozen more on calls about trespassers or unwanted persons in the building.

But Williams doesn't believe the three friends had nefarious intentions.

"In my heart at the time, I don't think they were in there to get copper," he says. "They were college students and they had heard through the grapevine that it's kind of neat to explore. That was their story, and I believe it."

It was a different situation in April 2006, when Williams and other officers took on an organized gang of as many as twenty copper thieves looking to strip anything they could out of the buildings to sell to the scrap yards. Usually they'd use the money they got to feed a meth habit, Williams says. Seven people were arrested immediately, but because the remaining suspects were spread out over multiple levels, officers called in the K-9 unit.

"When you get into the sub-basements, it's pitch black," he explains. "It's an old factory. It's a dangerous environment."

So dangerous that one of the police dogs was overcome by chemical fumes. Another crawled beneath a machine and fell into a pit filled with debris and fluid. "His handler crawled under the machine and tried to grab the dog. I held the handler's legs so he wouldn't fall in," Williams remembers. "And we pulled the dog out finally."

The dogs were taken to a veterinarian for treatment and are now back in service. One of the men arrested in that sweep, 48-year-old Robert Bordas, was later sentenced to four years in prison.

Ferd Belz, president of Cherokee Denver, says that break-ins have been a huge problem for the company. "We have a constant program where somebody breaks a fence, we come back in and rechain it," he explains. "In some places, we literally welded doors shut, and then people come in and break through welded doors. So it's just a constant, ongoing effort."

The sheer size of the site, coupled with the archaic design of some of the buildings, offers any number of permeable spots where trespassers can find entry. During the day, Belz says, the company relies on asbestos-removal workers and other employees to keep an eye on the property. At night it contracts with a security company to do patrols and "close things back up," he adds. "We've done everything that the police and insurance companies have advised us as far as posting it and making sure that things are sealed up."

Louis Adams would disagree.

For months, Adams waged a one-man campaign to warn the contractors and property owners of a dangerous, open shaft at Gates. The fifty-year-old Adams has no connection with Gates or the Polzin family. In a videotaped statement that Adams gave police, he said he first became aware of the "hazardous" shaft in March, when he decided to take an impromptu tour around the exterior of the site with his eight-year-old daughter, who's always had a thing for what she calls the "rubber band" factory.

Adams parked in a lot at the corner of South Broadway and West Mississippi, where a gate in the chain-link fence was wide open. It led to the alley that separates the huge Unit 10 from the smaller Unit 41, a four-story red-brick building originally constructed in 1971 as the administrative headquarters but shifted to engineering and product development in the '80s. Lifting his daughter so that she could peek in the windows, Adams saw a single-frame metal door to Unit 41 that was wide open. Telling his daughter to stay outside, he went through the door and nearly fell into the shaft himself.

Because the door led to a corridor that ended in a bank of windows on the far end, in low light the space looked like a long, continuous hallway. There was no visual suggestion that the walkway contained a pit — a large pit, since the shaft had been designed for a freight lift that was significantly bigger than a regular passenger elevator, with both a front and rear door. Alarmed by what he'd found, Adams took his daughter home and returned, alone, with a high-powered flashlight. He aimed it at the pit, and realized that a fall into that hole could be deadly.

Adams told police that he called any number he could find for contractors who might be responsible for the site, among them Alpine Demolition, which was in the process of tearing down adjacent buildings, including a 400,000-square-foot four-story warehouse south of Mississippi known as the Creamery Building.

Over the next few months, Adams returned to the site twice more. Each time, the gate was still unlocked, the door still open and the shaft still unsecured. After each visit, he left messages at Alpine, and after his third trip, he also called the DPD.

Adams went back to Gates again on September 2, and was furious when he saw that the shaft still wasn't secured. He called Alpine again, but no one answered over Labor Day weekend. The DPD did answer his call, though, and Officer Michael Samuels responded. After he surveyed the scene, Samuels was able to reach Alpine's owner, Jim Gochis, who then called Adams on his cell phone.

Gochis told Adams that units 10 and 41 were not Alpine job sites and were undergoing asbestos abatement by Misers Asbestos. While neither he nor any of his employees could legally enter that part of the property to secure the shaft, Gochis told Adams that he'd send some of his workers to lock the gate. Adams considered boarding up the shaft himself, but thought it was too dangerous and decided to leave it to professionals.

On September 4, Gochis met with John Allen, Misers' owner, and relayed Adams's concerns about the shaft.

Five days later, Adams was at home when a TV newscast reported that there'd been an accident at the old Gates plant and that someone had fallen into a hole in one of the buildings.

"Isn't that the elevator shaft you were always talking about?" his wife asked.

Adams ran out the door, headed for Denver Health Medical Center.

Until 2001, the Gates Corporation owned the entire 85-acre campus straddling two busy roads and a swath of heavy and light rail tracks. That December, the company sold fifty acres of the property west of Broadway to Cherokee Denver, a wholly-owned subsidiary of Cherokee Investment Partners. The North Carolina company is the world's largest equity firm specializing in cleaning up and developing so-called brownfields, or sites with high levels of contamination, including former power plants, Superfund sites and landfills. The deal indemnified Gates from any future responsibility for the significant soil contamination caused by eight decades of industrial use, as well as for the buildings it left behind on the site.

For a time, Gates retained ownership of the 35 acres east of Broadway, which had housed the company's headquarters and also a Samsonite factory, but in 2005 it sold the majority of that land to the Lionstone Group. The Texas-based real-estate firm demolished the 300,000 square feet of existing buildings and did some environmental cleanup; it plans to construct 2.7 million square feet of apartments and offices.

Cherokee Denver's plans are even more ambitious. Its property lies at the intersection of three light-rail lines and a major RTD bus station, and a successful buildout has the potential to emerge as one of the most important Transit-Oriented Developments in the region. A TOD is a dense, anti-sprawl development centered around a mass-transit hub, a style that re-emerged out of the new-urbanist push for walkable, urban neighborhoods with a mix of residential, retail and work space. With the passage of FasTracks, TOD has become the new buzzword for developers and real-estate companies that want to cash in on the fifty light-rail stations slated to be built through the metro area. But few of those stations are surrounded by so much open, if pre-used, space.

Cherokee Denver estimates that the environmental cleanup of the entire site will cost $24.5 million, with demolition running about $10.5 million. But then it envisions creating a $1 billion development that will function as a new mini-downtown. To accomplish this, it was granted a special "Transit Mixed-Use" zoning by the Denver City Council in 2003. According to design guidelines published for the site, this zoning designation allows for multiple buildings as tall as twelve stories surrounded by public walkways and parks. To finance the project, including necessary remediation work and then installation of the infrastructure, Cherokee was also granted $126 million in tax-increment financing subsidies by the city: The Denver Urban Renewal Authority is issuing bonds that it will repay from sales and property taxes generated by the development in future years.

Cherokee is functioning as the master developer of the project, dubbed Metropolitan Gardens. After it remediates the site and installs the infrastructure, it will hand off parcels to "vertical developers" that will actually design and construct the buildings. The Chicago firm of Joseph Freed and Associates will develop the majority of the property, Trammel Crow Residential the rest.

But first, the site must be cleared and cleaned. This fall, everything west of the rail tracks — including former warehouse buildings and bulk oil-storage tanks — was knocked apart and hauled off by demolition subcontractor Fiore & Sons. Units 10 and 41 are still undergoing asbestos abatement. Cherokee has yet to file demolition permits on those structures.

Johnny could squeeze your hand. He could give kisses. He could smile. But that was all. The tracheotomy prevented him from talking. His spine was broken, and he had sustained significant internal injuries, including a lacerated liver.

During visiting hours, his room in the ICU was always packed with friends, family and the random people Johnny had befriended. The same guy who'd given all these people bone-crushing bear hugs — in what became known as a "Johnny hug," he'd lift you off the floor and squeeze you with abandon — might never sit up again. His sisters plastered the walls and ceiling with pictures of flowers. They played songs by Johnny Cash. His mother, Donna, a registered nurse, could barely stand seeing her boy in that condition. He tried to cheer her up by making faces.

Johnny developed an infection and underwent several surgeries to fix liver abscesses and other procedures to repair his spine. They were planning to move him from Denver Health to Craig, where he'd start the long process of rehabilitation. One day, Johnny's parents noted with glee that a Stargazer Lily had suddenly sprouted and flowered in the family garden. It was unheard of this late in the season; it seemed like a sign. Johnny smiled when he heard the news.

After three and a half weeks in the hospital, he underwent a seventh surgery to repair another abscess. The procedure was only supposed to last an hour, but something went wrong. Johnny stopped breathing.

The doctors were sobbing when they came out to tell the family that he was gone.

It won't be long before Gates, too, is gone.

In late spring or early summer, Cherokee Denver will begin demolition on the remaining Gates buildings, the ones that everyone recognizes, the ones that fascinate explorers. Ferd Belz says the company hopes to preserve some of the facades and integrate them into future projects. "We're working with the state and historic folks at the city in terms of analyzing what we'll physically be able to save and what we can't," he notes.

But first the company has to figure out how to remove the stuff lurking beneath those buildings. "The challenge is that the site is pretty significantly environmentally contaminated," Belz says, "and a lot of it is in the soil and the groundwater under the buildings."

Some of it has even flowed off-site. In 2002, two employees of a drilling subcontractor working on a section of T-Rex directly north of the site became ill when they struck groundwater contaminated with trichloroethylene (TCE), an industrial solvent that's considered toxic to humans and was used to clean machinery in several Gates buildings over the years. Subsequent groundwater tests by the Environmental Protection Agency revealed that two underground plumes of the stuff had traveled below homes in West Washington Park. With heavy oversight by neighborhood groups and such organizations as the Campaign for Responsible Development, Cherokee Denver and the Gates Corporation embarked on a program of testing and mitigation that eventually reduced TCE in the area to allowable standards.

The Colorado Department of Public Health and Environment has more than 300 files relating to the Gates site, some going back to 1988. That was when the company discovered that a storage tank in the partially finished basement of Unit 29 had been leaking. Gates installed draining wells, and over the next seven years, the company reported it had to sucked up some 70,000 gallons of the sludge from the soil beneath the building. Cherokee has enrolled in the Voluntary Clean Up Program, which provides property owners with a state-supervised framework for remediating environmental contamination. Colorado started the program in 1994; since then, it has received 600 applications covering 400 sites across the state ranging from former laundromats to abandoned mines. Once state officials sign off on a site as clean, property owners like Cherokee can use that seal of approval to entice investors and secure other financial backing. In the meantime, Cherokee Denver has received $2 million in loans through the Colorado Housing and Finance Authority, according to Mark O'Grady of the state health department, which administers the cleanup credits. Ten VCUP applications for parcels on the Gates site have already been approved. Three others, including one for the parcel encompassing units 10 and 41, are still under review.

Unit 10 was originally built in 1917 and underwent major additions over the next four decades, until the last in 1961. It was in this building that the vast majority of the rubber-product manufacturing work was done, everything from mixing to milling, fabricating, curing and finishing. These procedures required the use of many hazardous and non-hazardous materials, including "latex, paraffinic process oils, plasticing compounds, chlorinated and non-chlorinated solvent cleaning solutions, formaldehyde, toluene, lead and chromium," according to health department files.

Beneath the foundations lies a huge mess of oil and solvents "with a high viscosity, i.e., equivalent to that of maple syrup," environmental investigators noted in a cleanup application submitted to the state. Cherokee plans to haul all of the dirt away and replace it with clean backfill before actual construction begins. Even so, any sub-grade parking structures must be built to allow ventilation not only for automotive exhaust but any chemical vapors that might float up from below. And any buildings constructed on the site will have a "sub-slab depressurization system" to ensure that any volatile organic fumes rising above state standards are not allowed to collect inside.

Such fumes could be deadly.

Word spread quickly that Johnny had died. It didn't make the papers this time, but everyone found out. People who knew him or knew of him. He was a friend, or a friend of a friend. He was family.

The Polzins scattered his ashes in Puget Sound and had a memorial bench installed in his honor at the Denver Botanic Gardens. Two months after Johnny's death, they are trying to find their way through their own labyrinth of grief. They wonder why it was that his life stalled in such a putrid place, deep in the dark where nothing could grow.

"He and I used to love going to the Gardens," says Johnny's mother, Donna. "He'd go with his friends from school. We bought a bench where we could just go and sit, in the Alpine Garden. It's better than some cemetery. He would have liked that."

They're taking another action on Johnny's behalf, too. They've hired an attorney, Jessica Allen of Isaacson & Rosenbaum, who's notified Cherokee Denver and Misers Asbestos that the family plans to sue the companies for failing to secure the area. (Misers Asbestos did not return calls; Cherokee Denver declined to comment on the accident.)

"You open the door, and five steps in, my son plummets thirty feet," says Larry Polzin. "The decision to do nothing was still a decision. They could've covered the pit, they could've chained the door, they could've welded it shut. And they did nothing."

True, Johnny went to Gates with the intent of trespassing on private property. But the legal theory behind the litigation is simple: If a property owner is aware of a hazard and does nothing to mitigate the danger, then the owner can be held responsible for injuries caused by the hazard. Johnny is gone, but others could be saved. Today, the doorway to Unit 41 is boarded up and secured. From the outside, you can't see the pit.

"It's pretty depressing, really," Joe Hicks says of Gates. "I want to go back again before it's knocked down completely." But he's also reluctant, given Helms's arrest and Johnny's death.

Talk of the old factory and what happened there fills an urban-explorers online thread. "I was gonna hit the shit out of Gates when I come for Christmas," one poster says. "Now that I read the guy died, I can also easily skip visiting it.... Falling scares the shit out of me."