"Any of the good stuff around here?" he asks.

A blue-jeaned lab worker shrugs. "It's back in the freezer now."

Keuer pokes around among jugs of clear solutions and cylinders of brown muck--ongoing experiments in product development situated in a back room of the small-scale manufacturing plant owned by Somatogen, one of Boulder's premier biotech companies. After a moment he emerges with a small bottle of reddish-purple liquid in one hand.

"Here we go," says Keuer, Somatogen's vice president of manufacturing and process engineering. He shakes the bottle and watches the crimson fluid ooze down its glass sides: an elixir rich and strange, sacramental, like a blessed Bordeaux. "This is close to what the final product looks like."

What it looks like is blood. Or, to be more precise, hemoglobin. Whole blood, as any ER junkie knows, is a seething mess of red cells, white cells and platelets, all suspended in plasma. Hemoglobin is the protein complex in red cells that carries life-giving oxygen from the lungs to the tissues; its high iron content is what gives blood its distinctive shade of red.

The stuff in Keuer's hand isn't exactly human hemoglobin, but it is, he notes, "pretty close." Somatogen's hemoglobin, registered under the trademark Optro, doesn't come from any human source; it's a mutant strain, genetically altered and grown in a laboratory, through a process not unlike the fermenting of beer. Yet it looks like the real thing. Under the right circumstances, it acts like it, too. And that might be close enough to earn Somatogen a chunk of the worldwide red-cell transfusion market, which the company estimates at around $5 billion a year.

That market is up for grabs, thanks largely to fears about the safety of the blood supply. In the wake of the AIDS epidemic, the monitoring of blood banks has improved considerably, but that hasn't quelled public concern about AIDS, hepatitis or other viral infections that can be acquired through transfusion. Surging hemophobia (fear of blood) has also been blamed for a critical drop in the availability of banked blood, even though there is zero chance of a donor becoming infected while giving blood.

"The public is panicked about blood safety," says Dr. Joseph Fratantoni, director of the division of hematology at the Food and Drug Administration's Center for Biologics Evaluation and Research. "They're demanding 100-percent-safe transfusions, which, of course, can't be delivered. Transfusion of blood is much safer than it was ten or fifteen years ago. But there's still a finite risk."

The chance of contracting the HIV virus from a transfusion in the United States is more remote than most people realize--about 1 in 150,000, according to the National Institutes of Health. But in some parts of Asia and Africa, the risk is as high as one in four, and contamination isn't the only problem with donor blood. It must be typed and cross-matched for compatibility, a time-consuming process that can be particularly trying in cases of accident victims with rare blood types. It has a short shelf life, from 35 to 42 days. And even a well-matched transfusion can result in a temporary suppression of the immune system, which leaves the patient more susceptible to post-operative infections.

The safest way to avoid such risks is to put aside several units of your own blood for use during an operation. But not everyone has sufficient warning of upcoming surgery, and the procedure isn't an option for certain cancer patients and others whose blood has failed them.

Hence the market--in theory, at least--for a blood substitute. Something in a magenta, perhaps, with all the oxygen-carrying capacity of hemoglobin and none of the risks associated with red-cell transfusions. Disease-free. One type fits all. Shelf life of a year or more.

Since the late Eighties more than twenty companies have joined the race to develop a blood substitute, spending hundreds of millions of dollars in the quixotic effort. Some tinker with hemoglobin extracted from animal blood or outdated human blood; others test totally synthetic products, such as oxygen-carrying chemicals known as perfluorocarbons. None have yet reached the marketplace, although an elite few are now roughly halfway through the FDA's gauntlet of clinical trials. Somatogen, for example, has successfully administered up to a hundred grams (four units) of Optro to surgical patients, believed to be the largest dose of a genetically engineered protein ever given to a human.

All the companies still have technical problems to overcome. Analysts who once predicted that a blood substitute would be commercially available by 1995 are now talking about 1999 or beyond. "There's clearly still work to be done," says the FDA's Fratantoni. "When I read reports that this material is likely to be approved in 1997 or something--I don't know where that's coming from."

Certainly not from Somatogen. The company's Securities and Exchange Commission filings are full of caveats and disclaimers, as befits the grim attrition rate in the biotech industry. (For every long-awaited miracle drug that meets with FDA approval, dozens of other products fail.) Still, that an obscure Boulder startup, founded in 1985 on plenty of brains but not much cash, could not only survive but emerge as a serious player in what may be the highest-stakes game of them all, is fairly miraculous in itself.

A mere two years ago Somatogen seemed to be under constant siege by impatient investors, shaken by management turnover and sniped at by stock-shorters and analysts skeptical of its recombinant hemoglobin technology. Its stock careened from a 1992 high of $50 per share to single-digit lows in 1993 and 1994--dragged down, in part, by reversals across the biotech industry. And it was hemorrhaging astonishing amounts of cash, a net loss of $23 million one year, $50 million the next.

Since those dark days Somatogen has stunned its doubters by demonstrating that it has licked some, if not all, of the fiendish difficulties involved in manufacturing hemoglobin outside the body. Among the true believers is pharmaceutical giant Eli Lilly, which entered into a joint development deal with Somatogen in mid-1994, agreeing to invest up to $35 million in the company and to share in the cost of bringing Optro to market. Several of Somatogen's rivals also are backed by big pharmaceutical concerns, but sealing the deal with Lilly--a company not only flush with cash but experienced in producing a genetically engineered product, human insulin, on a massive scale--gave Somatogen instant credibility.

"Lilly is one of maybe three companies that could pull this off," says Andr de Bruin, Somatogen's president and chief executive. "Johnson & Johnson is in this field now. Baxter is in. Eli Lilly, Upjohn--all the big pharmaceutical companies have decided to get into this field because it's a huge opportunity. Barring any surprises, it could be one of the biggest pharmaceutical opportunities that's out there."

For Somatogen to be successful, it will have to be able to manufacture pure, safe hemoglobin on a scale far in excess of even Lilly's insulin operation. We're talking metric tons, tanker trucks of the stuff, blood on wheels, the life-force shipped by air and rail to every corner of the nation and eventually the world.

At the moment, though, Tom Kreuer is thinking less about quantity than quality. He holds his little bottle of crimson magic up to the light, swishes it around and puts it back on the shelf.

"It's a fun protein to work with," he says.

Until recently, the quest for a better transfusion has been anything but fun. In fact, it's been downright bloody.

Attempts to use human blood in transfusion date back more than 150 years, but it was only as recently as 1900 that scientists figured out how to identify the different blood groups and avoid disastrous mismatches. It didn't take long for researchers to begin to explore less complicated procedures, including a possible blood substitute.

One major research contributor has been the U.S. military, which since World War II has sought a "resuscitation fluid" that could be pumped into wounded soldiers on the battlefield while they awaited a proper transfusion; experience had taught army surgeons that modest blood loss could be treated with saline or human serum albumin, but more serious injuries required an oxygen carrier.

In the Sixties a Harvard researcher demonstrated that an animal could be drained of blood, then kept alive--temporarily, at least--by use of an oxygen-carrying emulsion. Increasingly, though, attention began to focus on the body's own oxygen-delivery system: hemoglobin.

Removed from red blood cells, hemoglobin has potential advantages over red-cell transfusions, including compatibility with all blood types. But researchers soon discovered that injecting free hemoglobin creates other problems. Outside the cell, human hemoglobin tends to bind oxygen more tightly, releasing only a fraction of its wealth to the tissues, "like having money in the bank and not being able to spend it," as one researcher puts it. Worse, the "naked" molecule has a bad habit of breaking apart into pieces of alpha-beta peptide chains known as "dimers" that can be toxic to the kidneys.

"They killed an enormous number of experimental animals giving them hemoglobin," recalls Fratantoni, who's been monitoring blood-substitute research since the mid-Seventies. "There wasn't enough basic research done to understand what happens when you put free hemoglobin into an animal."

Results of various blood-substitute proj-ects were so discouraging, Fratantoni adds, that the entire field "dropped off the radar screen" for several years, "until AIDS rejuvenated it"--which is around the time Charles Scoggin became interested in the problem.

Scoggin, then a senior scientist at the Eleanor Roosevelt Institute for Cancer Research in Denver, had seen his share of transfusion problems in critical-care and lung-cancer patients. He also had served ten years on the faculty at the University of Colorado Health Sciences Center, which treated one of the first patients who contracted AIDS through a blood transfusion. "Once that connection was made, the paranoia went way up," he says.

Itching to make the move from pure research to more practical applications, Scoggin and two partners launched their own company, to be called Somatogenetics Inc., which would engage in developing a range of diagnostic and therapeutic products, including a run at a redesigned hemoglobin molecule. With Scoggin's connections in the field, he had no trouble getting the attention of top molecular biologists, but money was another matter.

"I got a second mortgage on my house and got really committed," Scoggin says. As the company's research began to focus more on hemoglobin, he made the rounds of three dozen venture-capital groups before he found a local firm, Capital Health Management, willing to assemble what would be the first of several phases of financing.

"There was a great deal of skepticism about whether you could even clone and express hemoglobin, much less take it to the levels of production to put it into pre-clinical testing," Scoggin says. "At that point people were only making very small amounts of recombinant protein. We were talking about making kilograms--amounts nobody had even envisioned, much less thought about putting into human beings."

Somatogen's approach to the problem was a serious departure from earlier efforts. Rather than trying to extract hemoglobin from human or animal sources, a procedure that still presents some risk of viral infection, Somatogen would grow the stuff in the lab, in a bacteria culture. And it would seek to make slight modifications in the genetic code of the molecule that would have a profound effect on how the molecule functioned, a process Scoggin describes as "instant evolution."

Because of free hemoglobin's tendency to break apart, "people were saying you'd have to make alpha chains in one fermenter, beta chains in another, and then you'd have to glue the molecule together somehow and make it so it wasn't selfish about oxygen," Scoggin explains. "Somatogen's real contribution--and believe me, this was a team effort--was reducing that to a single step, using genetic engineering."

Working in collaboration with the British Medical Research Council's structural biology laboratory (whose head, Max Perutz, won a Nobel Prize in 1962 for mapping the structure of hemoglobin), the Somatogen team was able to make several key alterations to the hemoglobin molecule. One was inserting an amino acid "hinge" that kept the peptide chains from breaking apart. Another involved changes in the chemistry of the chains that reduced the molecule's affinity for oxygen, so that more would be released in the body--more, in fact, than hemoglobin in red cells releases. The result was a mutant form of the molecule that, in animal testing, exhibited none of the toxicity problems associated with "native" hemoglobin.

But the new molecule was hardly perfect. In early human trials, healthy volunteers given small doses of Optro experienced a range of side effects, including nausea, vomiting, gastrointestinal problems and transitory fever. Scoggin says that the early trials didn't reflect how the product was ultimately going to be used, and that subsequent, more appropriate trials involving larger doses and anesthetized patients undergoing elective surgery have yielded less dramatic effects. In addition, the company has "tweaked" its purification process to address the fever and flu-like symptoms.

Still, negative reports from the early trials, combined with the kind of Wall Street buzz that's been known to bury other biotech companies, sent Somatogen's stock reeling. In the summer of 1992 syndicated financial columnist Dan Dorfman called Somatogen "a biotech dream turned into a nightmare, with more to come."

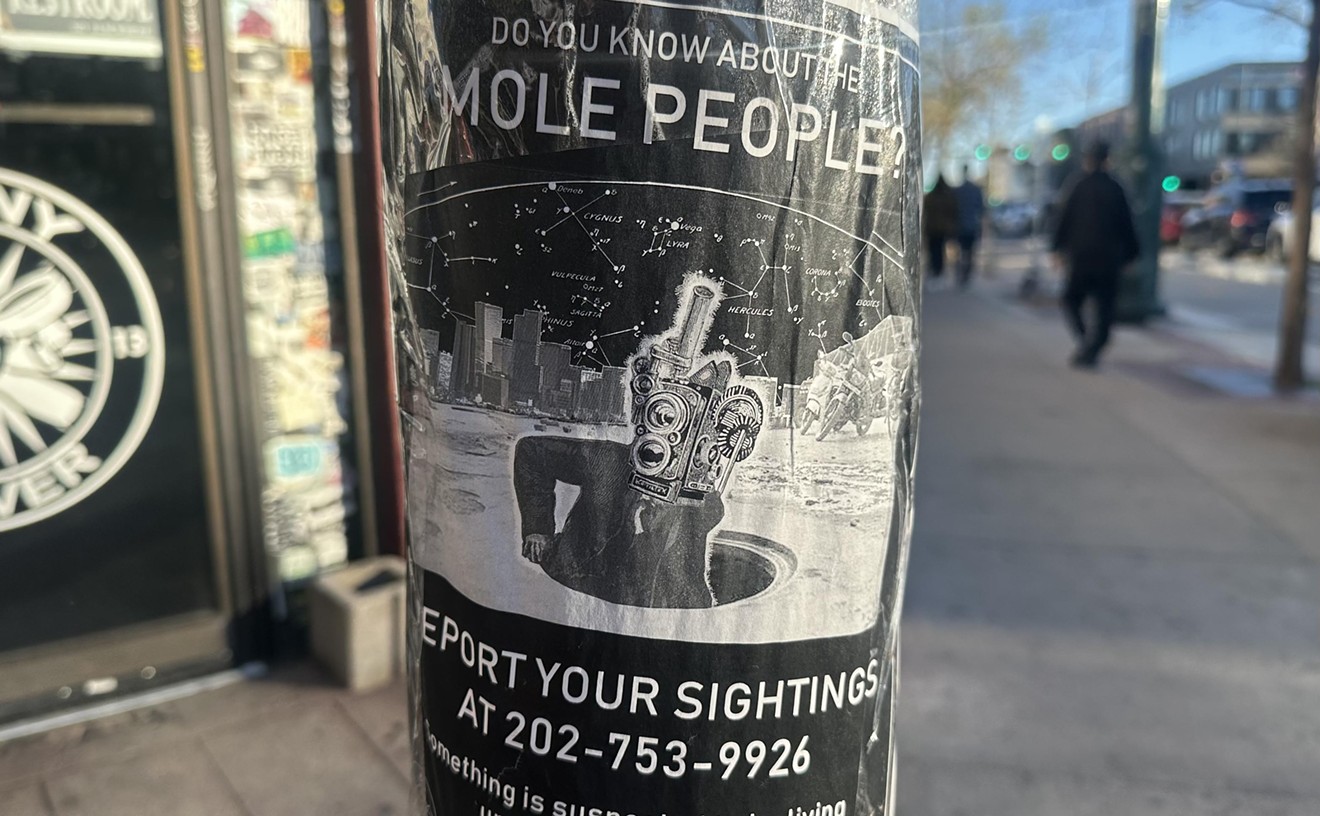

"I never had any idea who Dan Dorfman was until I got involved in this," Scoggin says. "We had rumors that we were doing our clinical trials with prisoners in Caon City. We had rumors that we'd been censured by the Presbyterian Church. Right after the Branch Davidian compound went up, the rumor was that we had to do a bunch of our trials all over again because some of our subjects were killed at Waco." Some of Somatogen's early tests were conducted in Austin, a long drive from Waco, but facts never seemed to get in the way of the fear-mongering about a company engaged in the exotic quest for a better blood supply.

Sometimes the rumors had nothing to do with Somatogen, but they cast doubt on the entire venture just the same. At least four of Somatogen's rivals in the blood-substitute race have abruptly suspended clinical trials in the past five years, for reasons they rarely share with their competitors. Scoggin likens the field to "walking into a dark room, knowing there are a lot of trapdoors out there."

In the fragile world of biotech, catastrophic events at one company have a disconcerting way of upending other, totally unrelated enterprises. Two years ago, the failure of Boulder-based Synergen's struggle to win FDA approval for its much-touted treatment for septic shock (a deadly blood infection) sent tremors throughout the Colorado biotech industry, in part because many of Synergen's institutional investors also held stock in companies like Somat-ogen. "When Synergen sneezed, we got a big cold," Scoggin says now. "It had nothing to do with what we were doing. It's as if Apple had a bad quarter and consequently Microsoft went into the tank."

Like a lot of other biotech entrepreneurs, Scoggin found he was putting more time into dealing with stock jitters and less in the lab. Shortly after the Lilly deal was announced, he stepped down as company president, prompting speculation that his ouster was one condition of the deal, but Scoggin says it was a decision he'd been weighing for months. Last fall he declined to stand for re-election as chairman of the board, citing his interest in moving on to other start-up ventures.

Yet Scoggin remains a major Somatogen stockholder and consultant. All those years of running interference with nervous stockholders and a scoffing financial press haven't dimmed his enthusiasm for the quest. One of his fondest moments in Somatogen's evolution came in late 1990, when the company moved beyond the test-tube stage to manufacturing record quantities of hemoglobin. The first batch was started on a bitter winter's night, in the midst of a blizzard, and a highly trained specialist had to be dispatched to the roof to knock ice off an exhaust manifold.

"We got things going," Scoggin recalls, "and damn if we didn't see hemoglobin come pouring out of the fermenter, on a scale that nobody predicted we could do. It was two o'clock in the morning, in the middle of a blizzard, and I thought, 'This is really kickass.'

"It was a short night, but I know I went home and got a good night's sleep--for the first time in a long time."

Tom Keuer uses an electronically coded card to open doors marked EMPLOYEES ONLY, and thus begins a vastly simplified lesson in how to make your own hemoglobin. Required ingredients: a homebrewer's kit, a dash of household bacteria, a patented recombinant protein, about $200 million and a few dozen biotech hotshots to help out.

"This is where the process begins," Keuer says, nodding toward a corridor window at a gleaming display of vats and gauges that looks suspiciously like the innards of a microbrewery. "It all starts when we take a small seed vial of E. coli out of liquid nitrogen storage and inoculate a shake flask."

Escherichia coli--or, in plain English, "that nasty stuff"--is a garden-variety bacterium, best known for its potentially lethal effects in humans when consumed in undercooked hamburgers. But E. coli also resides comfortably in the large intestine, and for years scientists have been using the stuff as a rich, rapidly reproducing medium for nurturing gene-spliced products. Somatogen's E. coli is a slightly modified strain, engineered to be virus-resistant and with the molecular structure of hemoglobin cloned into its genetic makeup.

Once thawed in a flask, the bacteria grows quickly. Within hours it's transferred to a 150-liter fermenter, then blown into a 1,500-liter tank. Kept slightly above room temperature, it's fed a tasty diet of salts, glucose, ammonia and other treats to ensure optimal growth. When the culture reaches a certain density, it's "instructed" to start "expressing" hemoglobin.

"You've got to inspire it," Keuer explains. "We use a chemical that sparks a genetic trigger that tells the bacteria, 'Okay, now we're going to make hemoglobin.'"

Over the next ten or twelve hours the fermentation tank turns, well, blood red. The mixture is then transferred to a pressurized chamber called a homogenizer, which bursts open the cells to release the hemoglobin and then scrapes away the cell debris. What's left is then rigorously sterilized and filtered in a "purification suite" to remove any remaining E. coli and other proteins the bacteria produces. Finally, gowned and masked Somatogen employees pour the purified hemoglobin into plastic containers to await final bottling off-site.

The entire process, from seed vial to joy juice, takes less than three days. The result is the only hemoglobin currently in development that doesn't depend on human or animal sources for its raw materials, but even Somatogen's rarefied red isn't entirely a product of the laboratory. The company supplements its protein with a tiny amount of "heme" (the iron-rich component in the hemoglobin molecule) extracted from New Zealand cattle--the only bovine source approved by the FDA for such use--in order to compensate for insufficiencies in the bacteria mixture. According to company spokeswoman Nanita Woolhiser, Somatogen is trying to improve its E. coli brew so the additional heme won't be required.

Yet the very presence of E. coli raises other safety concerns. The bacterium is good at producing not only hemoglobin but endotoxin, a poisonous byproduct that binds readily to hemoglobin. Keuer insists the company's purification procedure is more than adequate, though. "We can actually measure less endotoxin in our product than in similar preparations of human serum albumin, which come from human plasma," he says. "This is not an issue of product safety."

Over the years officials from other blood-substitute companies have openly questioned whether Somatogen could maintain product purity at a commercial level of manufacturing, which would involve cranking out thousands of units of hemoglobin a day, like so many bottles of Bud. Some also have wondered if the company was up to the task of building such a facility, which would require considerable amounts of water and cash. As if to rebut the naysayers, Somatogen broke ground on a proposed $45 million plant in Boulder's Flatirons Office Park in 1992, even as its stock was sliding and its cash reserves dwindling.

The plant was shelved a few months later, after the company struck its crucial deal with Eli Lilly. The agreement calls for Somatogen to continue to produce enough Optro for the current round of FDA trials, which are expected to last until mid-1997. Lilly will finance a larger facility to produce Optro for the final phase of the trials and for commercial use, and will jointly market it with Somatogen. The arrangement probably will save Somatogen upwards of $100 million in construction and operating costs; it also made believers out of some of the company's toughest critics, including its current president, Andr de Bruin.

De Bruin, a native of South Africa and a heavyweight in corporate health care circles, had been courted as Scoggin's successor for months, but he had put off his decision until the Lilly deal was finalized. He was impressed with the brain trust Somatogen had assembled on its board of directors--including key executives CR>CR>from Amgen, Genentech and other biotech giants--but he was even more impressed with Lilly's interest. It was Lilly, after all, that had taken Genentech's genetically engineered insulin to market, blowing animal-derived insulin products out of the water.

"They changed the market overnight," de Bruin says. "The fact that this company had the only recombinant hemoglobin was a very attractive part of the proposition. But without Lilly, I wouldn't have come."

The arrival of Lilly and de Bruin had an understandably tonic effect on Somatogen's prospects. Like most biotech ventures in the "pre-revenue stage," the company continues to bleed red ink, but its "burn rate" for 1995 was down to $1.5 million a month, considerably less than previous years' losses.

Robert "Pete" Peterson, a consultant with Denver's Hanifen Imhoff who has tracked Somatogen for years, credits de Bruin with bringing a "more controlled" management style to Boulder. "Charles Scoggin was good for the start-up phase, but Charles is more of a scientist than a broad-brush businessman," Peterson says. "The team over there now is keyed in on getting this thing commercialized and not disappointing stockholders."

De Bruin speaks cautiously of "not promising more than I can deliver" and of conducting thorough, methodical tests of Optro under a variety of conditions so as not to encounter surprises further down the line. He dismisses talk of an all-purpose arti-ficial blood supply as "a lot of fantasy and a lot of hype" and balks at the notion that Somatogen is racing against other companies to the finish line. As he sees it, various companies are developing entirely different "oxygen delivery systems" for different uses--elective surgery, in Somatogen's case, versus use in emergency rooms--and the market will probably support more than one product. He also stresses the importance of taking the long view.

"The CEOs of biotech companies walk this fine line," he says, "between needing to seed good news in order to get their compaCR>nieCR>s financed, and being realistic and conservative. The time lines for developing a product are typically far, far longer than what is communicated to the public. If Somatogen went out in 1989 and said, 'We don't think we're going to have a compound until the year 2000,' this company could not have been financed."

He adds quickly, "I'm not saying there is deliberate deceit. But the reality is there tends to be over-optimism in biotech."

Some skeptics think the company is still being overly optimistic. Last fall UBS Securities analyst Paul Kelly issued a highly critical report on Somatogen and Illinois-based Northfield Laboratories, which is developing a hemoglobin product from outdated human blood. Kelly argued that the products had too many technical glitches; that the fears about donor blood were overstated; and that the substitutes would be too expensive to be profitable in an increasingly cost-conscious health care system.

Other analysts, including a major biotech underwriter, jumped to the companies' defense. Peterson, whose company has no financial ties to Somatogen, rejects Kelly's report as the work of a "fairly inexperienced" analyst. "I, for one, don't want someone else's blood in me," Peterson says. "I don't care what the statistics are on AIDS. You still have hep B, hep C and other pathogens we don't know how to test for. I believe there is a market, and I think they'll keep the cost per unit down to an acceptable level."

Kelly didn't respond to Westword's requests for comment. De Bruin insists that Optro will be priced competitively with donor blood (currently around $200 per unit). UBS, he adds, expressed an interest in participating in the underwriting of Somatogen's latest stock offering shortly before Kelly's report was released. "Why would they want to be in on the financing, and then turn around and put out that report?" he asks.

The UBS broadside came on the heels of the $23.5 million offering and briefly drove the stock down by nearly a third, from $18 a sharCR>e to aCR>round $13; recently, though, Somatogen has been motoring along in the low twenties. "Our stock is still fragile, but it's much more robust than it was eighteen months ago," de Bruin says. "Paul Kelly said this stock ought to be trading at $8 a share. The market didn't believe him."

But does a market truly exist for Optro? The answer may have less to do with the actual state of the blood supply than with public perception. Somatogen is conducting its field trials with elective surgery patients--people who have a choice about whether to have that knee replacement or not, and who may want to have a choice about what kind of fluid goes into their veins.

"We find many people are scared of transfusions," de Bruin says. "We have had no shortage of volunteers."

Afew months ago Somatogen completed its "early Phase II" clinical trials of Optro. According to an industry publication, Bioventure View, twelve out of sixteen patients who were transfused with Optro during surgery reported feeling nauseous; four vomited. Nausea is hardly an uncommon response to surgery, though, and a company press release announced "no clinically significant treatment-related adverse events."

Expanded trials are currently under way at various hospitals in the United States and Europe. For Optro to meet FDA approval, the trials will have to demonstrate not only safety but efficacy--basically, that Optro delivers oxygen as well as or better than a red-cell transfusion, without significant side effects, and therefore can be used in place of donor blood for limited purposes such as elective surgery.

Fratantoni of the FDA acknowledges that "the risk factors" of Optro and the other hemoglobin products in the pipeline have dropped in recent years, but the field is still fraught with uncertainties. "We're farther along than we were five years ago, but that wasn't very far," he says. "In 1990 we didn't know what was going on. We'd inject hemoglobin, and the patient's blood pressure wouCR>ld go up,CR> and we'd start to see these weird symptoms: pains here and there, chest pains, muscle pains."

Fratantoni remains wary of the blood substitutes on several counts. There are still questions about blood pressure fluctuations and the possible release of free radicals, an altered form of an oxygen molecule that's been linked to cancer and other diseases. Another area of concern is the short half-life the compounds have in the body; after a day or two, the transfused product is metabolized in the organs, which could result in a need for further transfusions. Somatogen has "solved some problems by engineering changes into the molecule," he says, but other problems persist.

"I'm still enthusiastic about seeing these products get developed," Fratantoni adds, "because I feel there may be uses for them we haven't even thought of." He suggests that a product like Optro might be particularly useful in countries "that may never be able to develop a safe blood supply," as a stop-gap measure until the patient can be transported to a safer environment.

But Somatogen has bigger plans for Optro than simply the occasional pick-me-up for well-heeled tourists in Bangkok or Kinshasa. Andre de Bruin doesn't consider himself to be a starry-eyed idealist, yet he expects Optro's commercial launch target to be 800,000 units a year (20 metric tons). The availability of a safe alternative to donor blood will "dramatically impact how a physician thinks about how and when to do a transfusion," he says, thereby minimizing the possibility that patients will suffer from not being transfused enough.

There's more. Somatogen's research department is currently at work on a second-generation molecule and related products that could be used to treat anemia (by stimulating the production of red blood cells in the bone marrow) or to scavenge nitric oxide, which appears to play a role in septic shock, cirrhosis of the liver, organ transplant rejections and other maladies. "We definitely see this as a platform technologCR>y, from whicCR>h several products can come," de Bruin says.

It all sounds wildly improbable and vaguely romantic, like an old "Better Living Through Chemistry" filmstrip. About what you'd expect from the kind of people willing to invest hundreds of millions of dollars and years of frustration on a batch of fermented bacteria that might never turn a profit.

Charles Scoggin understands the yearning too well. His new startup is a medical information services company, to be called Rodeer--which, he explains, means "a gathering of cowboys, usually in the fall, for the purposes of rounding up stock." The venture promises to be quite different from his last one.

"I'm in danger of having to learn a new word here," he says. "It's r-r-r-"

Rodeer?

"No," he says. "R-r-r-revenues.