The North Face

Audio By Carbonatix

Rarely does a company worth nearly $6 billion reveal the processes of its top-performing brand. But for the first time last month, Denver-based VF Corporation welcomed media members into The North Face innovation lab in RiNo.

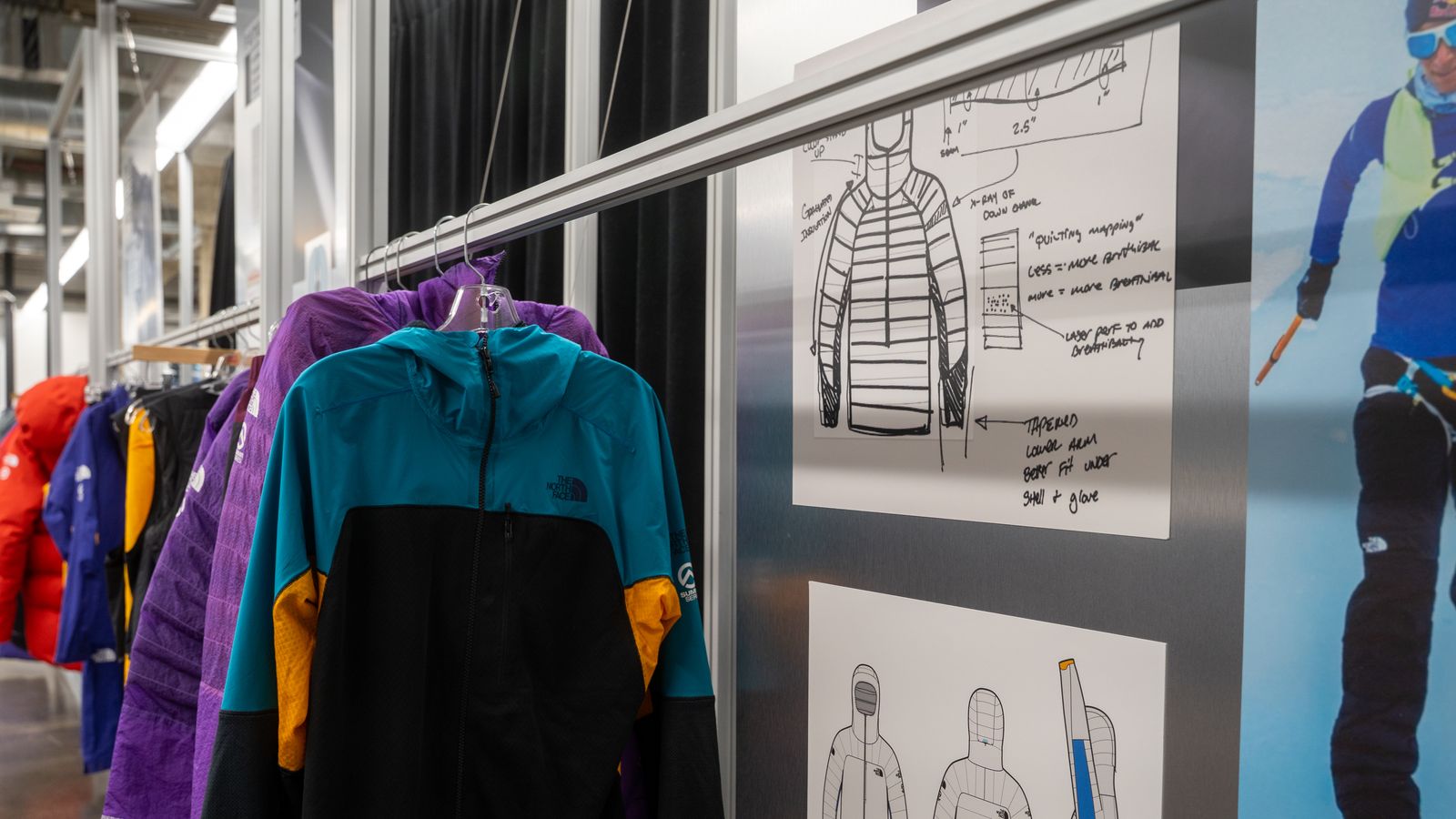

The presentation surrounded the launch of its Summit Series Advanced Mountain Kit, a 24-piece collection of innovative apparel, equipment and footwear designed for high alpine expeditions. The brand has developed a men’s 2.0 version, in addition to a women’s-specific model for the first time. More than magenta pink, it features tailored fits and technical insulation mapping based on gender-specific thermal testing that occurred not only in the lab, but out in the field.

The North Face

The popular outdoor brand differentiates itself through a global team comprising more than two hundred sponsored athletes, including the likes of rock climber Alex Honnold of Free Solo. For its latest product release, The North Face collaborated with several professional mountaineers including Christina Lustenberger who, while layered in the new women’s kit, completed a first-ever ski descent on the south face of Mount Robson, the most prominent peak in the Rocky Mountains.

“In the past, women would show up in an extra-small men’s kit,” explains Lustenberger, a former Olympic ski racer who’s set several first descents. She jokes that with this debut collection from The North Face, “You’re just going to see chics doing wilder and wilder things — while looking exceptionally cute.”

The North Face

Benjamin Védrines also contributed to field testing, simultaneously breaking the speed record on the second-highest peak on Earth. His summit of less than eleven hours is captured in the documentary K2: Chasing Shadows, presented by The North Face.

“Without the athletes, I don’t think we’d be pushing the edges this far,” says head of innovation Cory Olson, adding that the kit was designed for speed (a growing trend in mountaineering), comfort and protection. Alongside colleagues, he welcomed me and other journalists behind the scenes into the making of the Summit Series Advanced Mountain Kit and other products.

The North Face

The tour began in a spacious room full of colorful threads and textured fabrics. These included insulating materials sputtered with aluminum and titanium; a moisture-wicking synthetic wool that the brand has trademarked as DotKnit; and abrasion-resistant sheets interwoven with Spectra, a yarn that’s fifteen times stronger than steel by weight and a key feature of the new mountaineering kit. The same applies to AiryString zippers, a revolutionary tapeless design that limits bulk and rigidity with each tooth stitched directly into the fabric.

The North Face

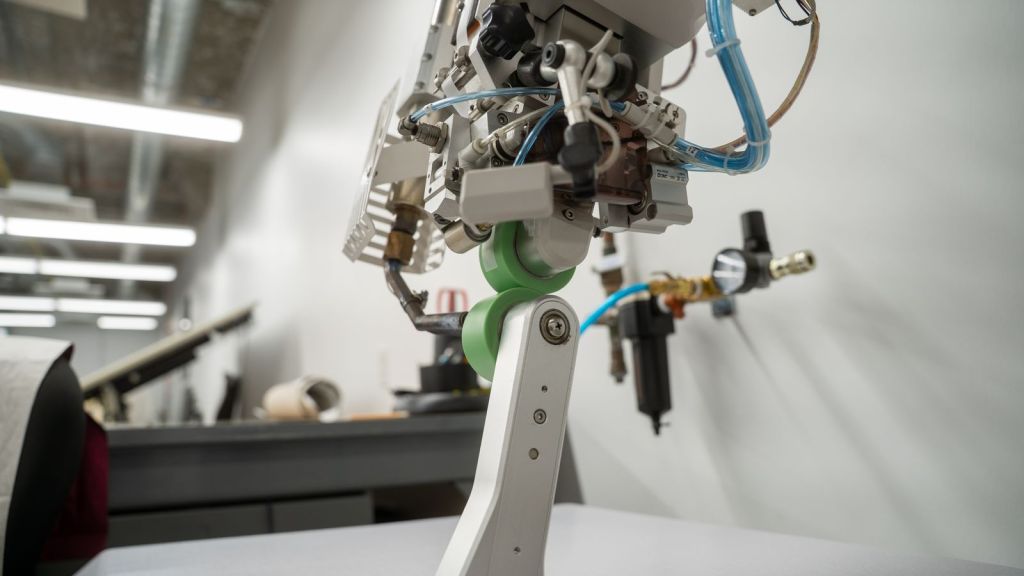

After demonstrating a conventional sewing machine, a tech took a perforated piece of fabric to a specialized seam sealer. Hot air and pressurized rollers applied an adhesive tape over the stitching, creating a fully waterproof material. Another sample fabric was then placed into a laser cutter with a heavy glass door, which allowed the group to watch as a beam etched intricate shapes into what would maybe become a windbreaker or an insulated vest.

The North Face

In the humid textile lab, fabrics from the prior developmental stage are tested against benchmark safety and quality standards set by ASTM International. Among the myriad machines was the Martindale, which simulates long-term wear of a material. According to the operator, it does this by applying “10,000 rubs” of sandpaper and other abrasive materials in a figure-eight pattern. Once the test is complete, any damage such as pilling, snags and holes is recorded and used to determine durability.

The North Face

Another machine called the Mace Snag Tester looked like something out of a Medieval torture chamber, with spiked metal balls bouncing against fabric stretched across rotating cylinders. It’s meant to mimic scraping against a rough surface, like a sidewalk or a rocky crag. Meanwhile, the Instron demonstrated material strength and puncture resistance, with a piece of a crampon impaling the tightly stretched piece of testing fabric.

Abigail Bliss

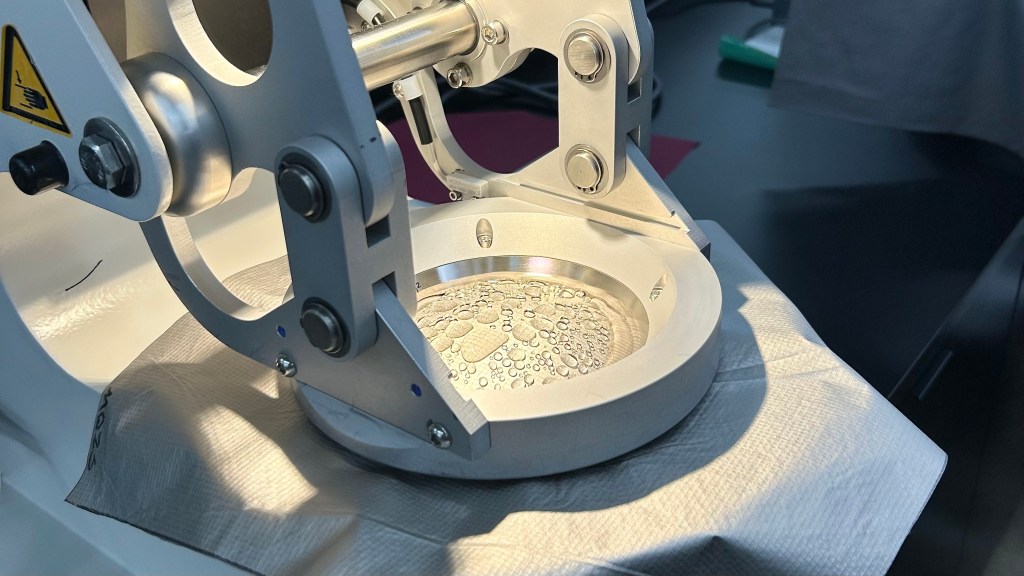

Inside the wet lab is the Bundesmann, a machine that simulates rainfall to determine a fabric’s water repellency. The hydrostatic head determined the same quality, but created a bubble of pressure to mimic different scenarios, such as sitting in snow or standing inside a tent set on a wet surface. I watched curiously as beads of water pushed through the taut metallic material. Other times, the test may result in diffused seeping or even blistering, with the moisture creating tiny, but damaging bulges in the fabric.

The afternoon provided an insightful look into the making of world-class outdoor gear, from everyday wear on the trail to the Advanced Mountain Kit. The latter collection is available for online purchase as of October 7, with ultralight insulated layers and complementary gear like the Summit Advanced pack, 135L duffel, Assault 2 ten and Superlight sleep system.