Helen Xu

Audio By Carbonatix

“Sausage is my life,” Steve Polidori says with a shrug and a smile before spearing another chunk of his Polidori Hatch Chile Cheese sausage and biting into it. Most people would rather not know how the sausage is made, but for siblings Steve and Melodie Polidori, it’s an obsession – it has to be. As the fourth-generation owners of Polidori Sausage, they’re upholding a legacy as Polidori Sausage celebrates a rare milestone: a century in business.

Today, Polidori’s headquarters and factory are in a 15,000-square-foot modern facility sitting on the edge of the quiet residential neighborhood of Park Hill. Walking inside, you immediately smell the delicious aroma of cooked sausages, most likely from the demo kitchen at the back of the offices. There are pig motifs everywhere, from the hand-painted rock doorstop and the pig statue greeting you at reception to pig door knockers. Every free space on Melodie’s office walls is filled with pig artwork and merchandise.

Look closer, and you’ll find a museum-like tribute to Polidori’s past – framed photographs, antique sausage tools and century-old documents dating back to the early 1900s, which is when the Polidori story begins.

How It Started

In 1914, Steve and Melodie’s great-grandmother, Anna Cerrone, emigrated from Caramanico in the province of Chieti, Italy, through Ellis Island and made her way west to Magna, Utah. There, she met and married coal miner Rocco Polidori. When his health began to decline because of black lung disease, they moved to Denver for the cleaner air and opened up a small grocery store on 34th and Shoshone in a building that still stands today.

Anna, Steve says, “was actually the butcher. She’s the one that’s known for making the sausages. People would come into the store and they’re like, ‘Oh, what’s that great smell?’ She was cooking it up in the back,” using heirloom family recipes from Italy. Eventually, Anna’s sons, Augie and Louis (Steve and Melodie’s grandfather), took over the grocery store. When Anna passed in 1982, the brothers sold the grocery store and Louis, who wasn’t fully ready to retire, moved the meat processing business to LoHi, just around the corner from the store.

Steve Polidori with framed photographs from Polidori’s history.

Helen Xu

What started as a hobby quickly escalated, and Louis needed help. Steve’s parents, aunts and uncles had stayed out of the sausage factory but in 1992, “My dad said to me, ‘You need a job. Your grandfather needs help. Get down there and help him,'” recalls Steve, who spent his last year of college commuting from Fort Collins to work alongside his grandfather.

Steve began to streamline and automate parts of the business – not without some pushback from the old man. “Working with my grandfather, there was a generation gap. … He came from the Depression era, so a dollar meant a little bit more than it did to us,” Steve says. “Everything was done by hand. There was no computer.” When he joined, the factory was using cylindrical hydraulic extruders with a 50-pound capacity. Steve convinced his grandfather to invest in portioning machines that could handle 400 pounds of meat at a time. Today, the factory has multiple versions of that machine, allowing it to produce 320,000 hot dog-sized sausage links a week.

Polidori once sold olive oil, deli meats and steaks alongside sausages at a handful of grocery stores; facing tough competition from restaurant suppliers Sysco and Shamrock, it dropped the other foodstuffs and doubled down on sausage in 2002.

Around that time, Louis retired and Steve realized he was now the one who needed help, so he rang up his sister and asked her to join the business. Melodie was working as a training and education consultant and, coincidentally, was looking for a job with more flexible hours and less travel so that she could spend more time with her children. In 2003, she joined the team and became Chief Sausage Officer.

“It took us a while to figure it out,” Melodie says of working with her brother, “but we’ve stayed in our lanes and we know what each other’s strengths and weaknesses are.”

Steve’s lane? “Production,” he says. His sister’s? “Everything else.” So Melodie runs the business side, including marketing, sales and finance.

Steve’s official title is the Sausage King, and he’s in charge of recipe development and the manufacturing process. His handwritten recipes are framed in Polidori’s demo kitchen. The business started with Italian sausage, but today, its products include hot Polish, kielbasa, Hatch chile cheese, andouille, bratwurst, breakfast sausage, chorizo, meatballs, sausage crumbles and chicken sausage, as well as a Never Ever Any Antibiotic line of sausages. In all, Polidori produces eighty different products in various flavor profiles, shapes and sizes.

Keeping It Natural

Over the last 100 years, Polidori Sausage has grown in terms of products, employees, sales and customers; its facility has grown, too. In 2016, it moved from its original LoHi space to its current Park Hill location. But one thing the family refuses to modernize is the historic definition of a healthy, clean product. “The secret is, we really haven’t deviated from our great-grandmother’s recipe,” says Melodie. “Pork, salt, spices. That’s it. No water added, no fillers, no nitrates. We’re not trying to cut any corners.”

Polidori’s portioning machine piping out sausages.

Helen Xu

A scrolling banner on every page of its website reads: “All natural, gluten free, made from premium pork shoulder, no preservatives, no soy, no nitrates, no sugar, no MSG, no artificial colors or flavoring.” The same wording appears on all Polidori packaging.

The siblings slam their competitors for taking the opposite approach “They fill it full of junk!” Steve exclaims. “They didn’t use any of that stuff back in the day, why do we have to use it now? Now [our competitors] put in shelf stabilizers that are not good for you so they can produce millions of pounds and go throw it into some warehouse somewhere and it stays good for two years out of the freezer.”

Polidori Sausage makes fresh sausages every Monday and Thursday in a processing room set to 34°F. Then, they’re shipped out in refrigerated trucks to retail customers. Those sausages are good for eighteen days. For food-service customers, the product is frozen to give it a four-month shelf life.

How the Sausage Is Made

Despite the complicated-looking equipment, the processing room is deceptively simple. Gigantic cardboard totes of pork shoulder (Melodie calls them “bathtubs of pork”) are fed through a grinder, mixed with spices, and then sent through a portion-control machine that pumps out set shapes and sizes of sausages, be they links, patties or strips. The last step is for all the sausage to go through a metal detector to guarantee that no bits of metal have made their way into anyone’s food.

The spice room contains no bins of preservatives, no boxes labeled with long, tongue-twisting chemical names. Instead, a quarter of the room is taken up by bins of raw spices. The rest is filled with boxes and boxes from Rocky Mountain Spice Company, which makes many of Polidori’s spice blends, including its mild Italian sausage seasoning – the label reads simply “salt, black pepper, red pepper, paprika and chili pepper.” One classic Italian sausage ingredient is missing from that list: fennel. That’s because great-grandmother Anna’s recipe calls for the fennel to be freshly-cracked into the ground pork right before stuffing, so that’s what Polidori Sausage still does.

Bathtubs of pork shoulder ready to be processed into sausage.

Helen Xu

Over a century in business, the Polidoris have encountered a challenge or two. Because the headquarters is a meat-processing plant, it is visited every day by the USDA and audited annually – last year, it got a 98 out of 100. “The federal regulations aren’t where we [struggle], it’s our local regulation,” says Melodie. “It’s trying to do business in Denver – the regulations, the bureaucracy to try to get anything done. It’s the layering of more and more rules and regulations that makes it a little bit challenging.”

It’s become so challenging that the Polidoris vocally muse about looking outside of Denver for their next location. But they wouldn’t move far – so much of the business is concentrated here. The majority of the retail locations at King Soopers, City Market and Safeway are in the greater Denver area. But retail only makes up 20 percent of the actual business; the vast majority comes from food service. Even if you’ve never bought a Polidori sausage at the grocery, you’ve more than likely had Polidori sausage.

It’s the official sausage of the Colorado Avalanche at Ball Arena and it can also be found at Coors Field, as well as numerous local restaurants such as Wooden Spoon Cafe & Bakery, Onefold, Fox and Hen, and Snooze. Polidori’s top-selling item is chorizo because of its popularity with Denver’s Mexican restaurants, which love it because “it’s not made with butts, guts, lips or jowls. We have a very high yield, 80-to-18 fat-to-lean ratio, and it’s kind of a gringo Mexican sausage,” says Melodie.

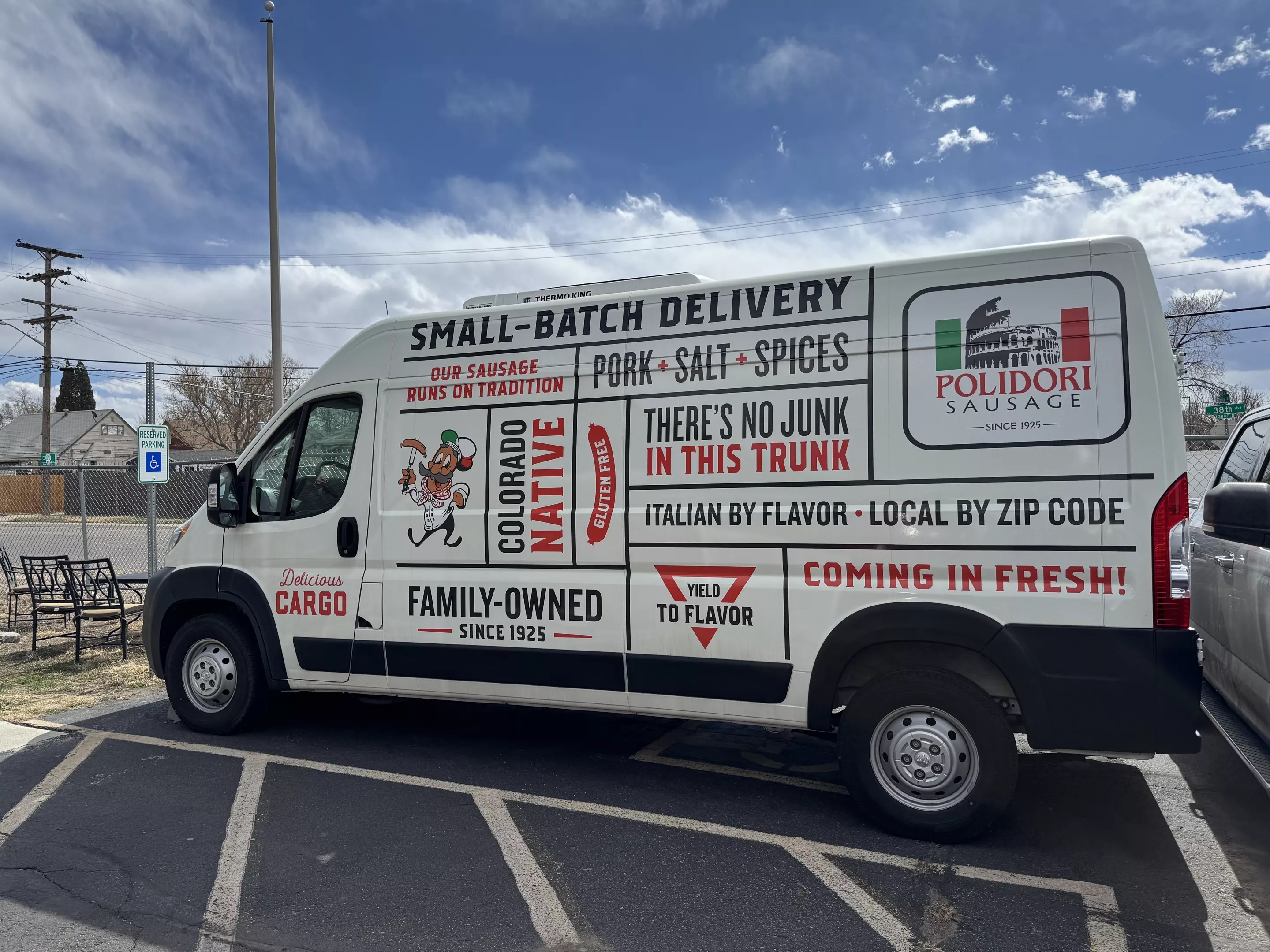

Polidori Sausage is on the move.

Helen Xu

The Future

While the business has come a long way from that small grocery store, Steve and Melodie aren’t taking their hands off the wheel anytime soon. “We’re having a lot of fun in what we’re doing,” says Melodie. “Obviously, there’s a lot of weight on our shoulders turning 100.”

In celebration of that milestone, the company created a custom 100th-anniversary logo for its packaging and debuted a cheddar jalapeño bratwurst. On opening day at Coors Field, it also unveiled two anniversary-themed concession carts. In the coming months, the company is hosting barbecues all around town for its distributors, workers and drivers. “We’re going to basically coin ourselves as the official sausage of summer,” Melodie says, laughing.

For 100 years, the Polidori family has stayed true to it craft, outlasting competition and navigating an ever-changing regulatory landscape – all without compromising the integrity of great-grandmother’s recipe. As the company marks its centennial, it remains focused on the same simple formula that started it all: hard work, family and damn good sausage.